-1140x400.png)

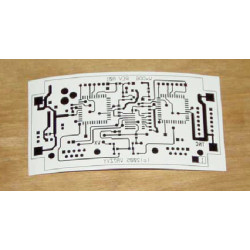

So here is a mind-blowing thing. You take any gadget, such as a phone, a remote control, a TV-whatever it is-and there is something greasy with bright lines all over it. That’s a PCB. And most likely, it’s one of those Copper PCB Boards doing all the silent work inside.

Now, not gonna lie, people barely notice these things. But without them, your electronics are just fancy boxes of plastic and metal. Copper PCBs are what connect everything and make the magic happen.

What Exactly Are Copper PCB Boards?

In simple words, Copper PCB Boards are those circuit boards that use copper tracks to move electricity between components. Copper is the main hero here - because it carries current super efficiently and doesn’t heat up too fast.

These tracks are kind of like roads, helping electric signals travel smoothly. From LED bulbs to your laptop’s motherboard - it’s all copper running the show.

Why Copper Is So Important

Let’s be honest - there are other materials out there. But copper? It’s just too good to replace.

A few solid reasons why copper rules PCBs:

It conducts electricity better than almost anything.

Handles heat like a champ.

Lasts long even in tough environments.

Easy to shape and etch for small circuits.

So yeah, it’s reliable, strong, and efficient. No wonder almost every good PCB uses copper.

Types of Copper PCB Boards

Now this is where it gets interesting. There isn’t just one kind of Copper PCB Board.

Depending on how they’re built, there are a few main types - each with its own vibe and use.

1. Single-Sided Copper PCB Boards

The classic one. It’s got copper on only one side of the board, and components sit on the other.

You’ll find these in:

LED bulbs

Power adapters

Simple DIY projects

They’re cheap, simple, and easy to make. But yeah, not great for complicated circuits.

2. Double-Sided Copper PCB Boards

As the name says, copper on both sides. Connections are made using tiny holes called vias.

Common uses:

Power amplifiers

HVAC controllers

Industrial gadgets

They’re a good mix - not too simple, not too complex.

3. Multi-Layer Copper PCB Boards

Now we’re talking big leagues. These boards have multiple copper layers stacked with insulation in between. You can fit more circuits in less space - neat, right?

Used in:

Laptops and desktops

Smartphones

Aerospace and medical tools

They’re expensive and tricky to make, but totally worth it for high-performance stuff.

4. Flexible Copper PCB Boards

These are the best ones. The process of the materials forming is a characteristic of such materials as polyimide; they can twist, turn, and fold without getting damaged.

In the following items:

Smartwatches and other wearables

Mobile phones that can be folded

They withstand the conditions of pressure, heat, and vibration without losing.

5. Rigid Copper PCB Boards

Now the opposite of flexible ones. Rigid boards don’t bend at all - built for strength and stability.

Used in:

Computer motherboards

Car systems

Heavy machines

They can take pressure, heat, and vibration without giving up.

6. Rigid-Flex Copper PCB Boards

A sort of combo deal - part rigid, part flexible. Consequently, it is strong where it needs to be and flexible where it assists in saving space.

Used in:

Medical devices

Military equipment

Compact electronics

They cost more but reduce wiring and improve durability.

Applications of Copper PCB Boards

Honestly, these boards are everywhere. You just don’t notice them because they hide under covers and casings.

Here’s where they show up:

Consumer Electronics: TVs, phones, tablets, speakers.

Automotive Systems: LED headlights, sensors, control units.

Industrial Machines: Motor control, automation systems, heavy circuits.

Medical Tools: X-rays, scanners, portable monitors.

Communication Gear: Routers, satellites, data servers.

Pretty much every electronic system you touch daily has one of these boards inside.

Choosing the Right Type of Copper PCB Boards

The choice of the Copper PCB Board type perfectly depends on the application. Here is a quick cheat guide:

For small, basic stuff → go Single-sided.

For slightly advanced circuits → Double-sided works best.

For powerful and compact designs → Multi-layer.

For flexible gadgets → Flexible or Rigid-Flex.

For strong, industrial gear → Rigid is the way.

You just match your project’s needs with the board’s ability - simple as that.

Final Thoughts

Let’s be real - Copper PCB Boards don’t get enough credit. They, without making a sound, take care of all the heavy lifting in your devices. It does not matter whether it is a smartwatch, a drone, or a huge industrial motor; copper boards ensure that everything is connected, that there is communication, and that everything operates as it should.

They may be plain in appearance, but without them, no modern electronics would exist. So yeah, next time your gadget powers on perfectly - thank the copper beneath it. Buy now!

FAQs

1. Why is copper used in PCB boards?

The answer is that it is an excellent conductor of electricity and remains stable at high temperatures.

2. What is the distinction between single-sided and double-sided PCBs?

Single-sided only has copper on one side, while double-sided has it on both - for more complex circuits.

3. Are flexible copper PCBs durable?

Yes, they bend easily but remain strong and reliable.

4. Where are multi-layer PCBs used?

Primarily in laptops, smartphones, and advanced electronics.

5. Can I make one at home?

You can try making simple single-sided boards, but advanced ones need proper machines and tools.

Leave a Comment